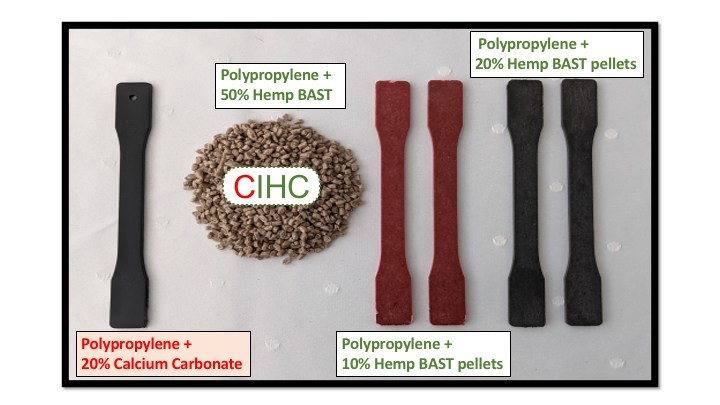

An Eco-Friendly Alternative to Plastics

LEWES, Del. – Plastic material manufacturer Canadian Industrial Hemp Corporation (CIHC) announced their initial product, a plastic pellet for injection molding.

The material will cost less than common plastics and feature better performance and an attractive surface finish.

The plastic compound, made with agricultural waste, is better for the environment, and is to be manufactured using the company’s patent-pending technology for increasing quality, consistency and production efficiency.

Demand from North American plastic manufacturers is expected to be greater than the capacity of the company’s first planned production facility to be located in Vegreville Alberta, and the company is currently evaluating potential sites in North Dakota for a second factory.

The automated flax and hemp stalk processing equipment is being sourced from Cretes AG, of Belgium. The same equipment is already being utilized by large processors in Europe and Asia.

Large plastic manufacturers in Europe are already using flax and hemp. By building the first flax and hemp stalk processing facility in North America to produce plastic pellets using a fully automated production line, CIHC will offer lower prices than existing competitors.

Robert Ziner, Founder and CEO of CIHC said “We have completed stage 5 engineering and run injection molding trials to ensure that we can offer a cost-effective material to North American plastic manufacturers. Because our product costs less than what is being used today, there’s an immediate opportunity to help the environment, farmers, and end-users who will enjoy lighter and stronger plastic products.”

(This information is primarily sourced from Canadian Industrial Hemp Corporation. Highly Capitalized has neither approved nor disapproved the contents of this news release. Read our Disclaimer here).